The second-stage cell of the multistage system, where the 23.4% caustic solution is concentrated to 30% by weight NaOH, operates at four.25 volts at a current effectivity of 93%. In the next Examples, the impact of the instant course of on power savings and membrane life extension is illustrated. Also, to facilitate understanding of the principles involved within the immediate process, a linear relationship was assumed between the caustic concentration caustic soda price 2020 within the catholyte compartment and cell voltage, present effectivity and membrane life. In other words, at high caustic concentrations, the cell voltage increases, the cell efficiency drops and the life of the membrane decreases. Conversely, at lower caustic concentrations, the cell voltage decreases, the cell effectivity will increase and the lifetime of the membrane is prolonged.

Capital funding and membrane substitute amount to 25% and eight%, respectively, of the total manufacturing value. Maintenance of a excessive present density reduces the original plant capital funding and the membrane replacement costs.

In caustic flakes will react with water in the mercury cell to type Sodium hydroxide and Hydrogen as by-product. In the membrane process, the ion change membrane acts as a barrier to all gasoline and liquid flows, and solely sodium hydroxide permits the passage of sodium ions between compartments. The sodium ions pass in hydrated kind to supply sodium hydroxide within the cathode where hydrogen is given off.

Considerable membrane growth work has been done using, primarily, numerous formulations of perfluoro sulfonic acid and perfluoro carboxylic acid sort resins. Each of these membrane formulations has particular properties which differ with the working circumstances. A particular membrane materials may have wonderful present efficiency traits at a forty% caustic concentration, however might have a short life under these conditions. As a result, the cell operating circumstances and business membrane materials in use at present characterize a compromise geared toward attainment of the most effective achievable product cost. Small quantities of nitrogen trichloride, an unstable and highly explosive compound, can be produced in the manufacturing of chlorine.

Demand for caustic soda is increasing. World over plants are shifting from mercury technology to membrane cell process. This will curb the production for a year or 2, hence demand of caustic soda should be good. Gujarat alkali has all the essence to be a 4 digit stock.

— IKSmallCaps (@IKSmallcaps) September 8, 2018

Patent Citations (

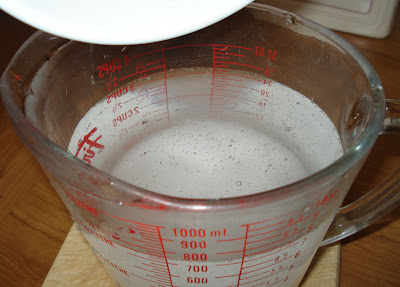

Saturated brine, prior to the electrolysis, is purified to precipitate calcium, magnesium and different detrimental cations by addition of sodium carbonate, sodium hydroxide and different reagents. The suspended solids are removed caustic soda suppliers from the brine by settling and filtration. Sodium hydroxide and chlorine are manufactured together by the electrolysis of sodium chloride.

The membrane is a copolymer of tetrafluoroethylene or an analogous fluorinated monomer. In the mercury cell, sodium is discharged in the form of a mercury sodium amalgam and chloride ions as chlorine.

- This course of passes an electrical current through the brine and attracts ions within the resolution to the positive and unfavorable terminals.

- In the current invention, vital improvements can be achieved by use of a multistage operating mode, significantly so far as energy consumption and membrane life are involved.

This technique is also utilized in refining processes such as the purification of bauxite (Figures 2). causes environmental contamination – through the production of sodium hydroxide, there are mercury losses that enter the water, air, soil, waste and the product itself.

Vynova has demonstrated industry leadership through an aggressive capital funding program for conversion to membrane cells across all its facilities. The PDF photographs may be utilized in scientific or technical publications if the supply mentioned. On the cathode, hydrogen gasoline types as water is cut up, which bubbles out and is collected.

Converting from Mercury to Membrane Cells

In 2001, the European chlor-alkali sector formally dedicated to a gradual phase-out of mercury cell know-how by 2020. There are three key ingredients to make elemental chlorine; salt, electrical energy and water. From these three components, we get elemental chlorine (Cl2), caustic (often sodium hydroxide or NaOH) and hydrogen (H2). As these three merchandise are highly reactive, applied sciences have been developed to keep them aside.

It is this cellulose which after further purification varieties the basis of paper. Sodium hydroxide is used in a wide range of industries as may be seen in Figure 1. Much is used to clean gases to remove acids before emitting them to the open surroundings. For instance gases emitted from burning fossil fuels which include appreciable quantities of sulfur dioxide. There are many ways of trapping the sulfur dioxide, one which is used broadly entails scrubbing the gases with a solution of sodium and calcium hydroxides.