Rapid Prototyping INTRODUCTION

China plastic injection molding manufacturer

The manufacturing world has been revolutionized by the emergence of rapid prototyping, an umbrella term for a range of manufacturing techniques that can fabricate prototypes and parts in a quick and cost-effective manner. This space has grown immensely over the past few decades, and as methods like additive manufacturing, CNC machining, injection molding and vacuum casting become more affordable and accessible, rapid prototyping has become an integral part of product development across all industries.

In the following guide, we’ll cover every aspect of different rapid prototyping techniques and applications, showcasing the different processes, advantages and common applications. Whether you’re looking for the right rapid prototyping method for your own production plans, or simply want to learn more about the various technologies available to you, our Rapid Prototyping Guide has everything to help you make an informed decision on which prototyping path you venture down.

What is Rapid Prototyping?

Across nearly every industry, rapid prototyping is changing the way that manufacturers are approaching product design and production. The most accurate definition of rapid prototyping can be stated as follows:

Rapid prototyping is comprised of an array of production techniques that are used to take a 3D model and quickly fabricate a scale model of a physical part or assembly.

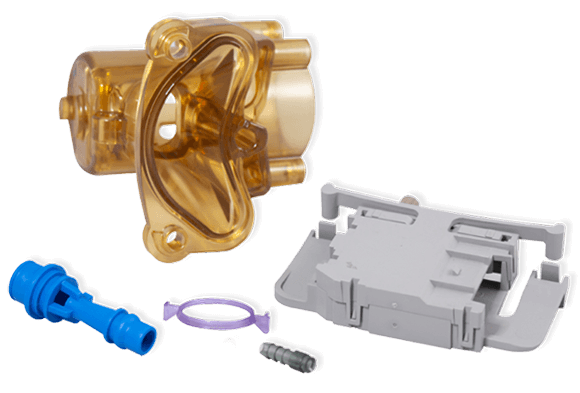

The most popular form of rapid prototyping is called additive manufacturing (also known as 3D printing). There are a number of 3D printing technologies, each of which is compatible with different materials and offers distinct benefits. Other technologies that are capable of rapid prototyping includes CNC machining, injection molding and vacuum casting.

Why Should You Use Rapid Prototyping?

1. Bringing Design Concepts to Life – First and foremost, one of the biggest advantages of rapid prototyping is that it allows you to realize design concepts in the physical world. When developing a product or part for mass production, the ability to create physical prototypes is a crucial part of the process. Rapid prototyping provides an affordable and quick way to iterate your design for mechanical testing and to ensure the dimensions match the designer’s intentions.

2. Reducing Production Costs and Time – Rapid prototyping can also greatly reduce overall production costs. For example, additive manufacturing technology eliminates the need for moulds, patterns and special tools, which are oftentimes quite costly. Additionally, using rapid prototyping techniques will allow you to optimize and repair any potential flaws in your design before it’s sent off for mass production.

Free shipping coupon code: "freeshipping" on any order from yiannopoulos.net

In the manufacturing world, time equals money, so you’ll be pleased to hear that rapid prototyping also reduces the time needed for the product development process. With rapid prototyping, you can quickly iterate your design and ensure that it’s ready for mass production in a time-efficient manner.

3. Make Changes Quickly – Not only does rapid prototyping help bring your design concepts to life (as we mentioned earlier), it also enables designers and engineers to make quick changes to their product or part on a whim. Let’s say you create a prototype of a part. Once you have it in your hands, you suddenly realize that there’s something you can repair or optimize to reduce mass production costs or improve the user’s experience. With rapid prototyping technologies like 3D printing or CNC machining, you can modify or repair a design and have it iterated in the nick of time. Instead of realizing where the mistakes are during the mass production process, which can setback production time and costs, rapid prototyping makes it easy to make changes to your design without having to invest too much money or time.

4. Customization – Rapid prototyping also makes it possible to develop highly customizable parts and products that meet individual requirements. Since no tooling or process is needed with these manufacturing techniques, it’s easy and relatively cheap to personalize and reiterate your model.

When using traditional manufacturing techniques, even minor changes in a design will alter the entire production process. But with rapid prototyping methods like 3D printing or CNC machining, these changes can be implemented without impacting the overall manufacturing process. This is a major benefit for both companies and consumers, as parts can be given a highly personalized touch.

5. Reduce Design Flaws – With rapid prototyping processes like additive manufacturing, you are able to physically produce a part or product and ensure that there are no design flaws. By using plastic or metal material that resembles the one that will be used to produce the final product, you can conduct physical tests to see if the properties and part strength meet your requirements. This allows companies and manufacturers to discover flaws or functionality issues in the early stages of product development stage, saving an immeasurable amount of time and money.

Types of Prototypes

There are a number of terms used to characterize various types of prototypes. With rapid prototyping in particular, you’ll find that there are numerous styles to choose from, each tailored to meet different production demands. Here is a brief overview of the terms that encompass the world of rapid prototyping.

1. Looks-like Prototype – A “looks-like prototype” is a primarily aesthetic part. This kind of prototype is focused on replicating the outer appearance and usability of the product, valuing the visual aspect over the functional. A looks-like prototype can be used to create a perception or provide a first impression of your product to customers, impacting the buying decision and how the end-product will be received on the market. Although this style of prototype can be created out of nearly any material, FDM 3D printing technology has become an increasingly popular technique due to its ability to create complex geometries at an affordable price

2. Works-like Prototype – A “works-like prototype”–better known as a functional prototype– is meant to showcase to core functionality and mechanical abilities of your part or product. Aside from the physical object itself, it’s also common to utilize development boards and other electronic components to demonstrate how the prototype will work in its final form.

This type of prototype doesn’t necessarily have to show off the visual quality of your product, and can sometimes look like wire spaghetti or a makeshift object. But that’s okay. The main purpose here is to test the functionality of your design. And so, when you’re designing for a works-like prototype, the material you choose is just as important as the manufacturing process. It’s important to select a material that resembles the mechanical properties of the one that will be used in mass production. Therefore, injection molding, CNC machining, vacuum casting or industrial-grade 3D printing will likely be used in these cases.

3. Hybrid Prototype – A hybrid prototype is one that combines the visual aspect and mechanical aspects into one product. This type of prototyping is useful when refining the aesthetics and form of your product, while also testing the functionality and placement of electronics. Using rapid prototyping techniques like CNC machining or 3D printing, you can create a hybrid prototype that replicates both the aesthetic and mechanical value of your product.

4. Pre-production Prototype – Last but not least is the pre-production prototype, which you can probably guess is a prototype that is close to replicating the end-product. This type of prototype is usually produced with a manufacturing process that is either the same or similar to the one that will be used in mass production. This is when CNC machining and injection molding becomes the go-to rapid prototyping technique. The purpose of pre-production prototypes is to identify and solve any potential problems before entering the final production phase. With this type of prototype, you can check all specifications and apply for necessary certifications. Since this is the final step before mass production, most engineers and manufacturers use this opportunity to ensure the design is optimized for manufacturing. In order to guarantee a successful production workflow, you should take a number of factors into consideration, including manufacturing, pricing, usability, transportation, user experience, sustainability and more.

How to Get a Prototype Made?

Depending on the type of prototype you need to make, there are a few different paths you can take. If you need to produce a prototype that will only serve an aesthetic purpose and requires little functionality, you can invest in your own 3D printer or CNC milling kit. The desktop 3D printer market is spilling over the brim with a variety of options.

Whether your focus is affordability, reliability or part quality, chances are there is a 3D printer that will suit your rapid prototyping needs. CNC milling kits have also become an increasingly affordable and accessible product for designers, engineers and small businesses.

However, if you need to create a functional prototype or a prototype with exceptional visual quality, the best option is to employ a rapid prototyping service to do the dirty work for you. By utilizing a rapid prototyping service, it provides the opportunity to use any manufacturing technique and material available. With professional manufacturing services like Yiannopoulos, you also receive expert assistance on how to optimize your design and which rapid prototyping technique is ideal for your needs.

All in all, you can invest in your own rapid prototyping technology and quickly iterate and refine aesthetic prototypes that don’t require advanced mechanical properties. However, when you need a functional prototype that will encounter stress, high temperatures, conductivity or other environmental characteristics that are commonly found in real world applications, your best bet is to enlist the help of a Yiannopoulos rapid prototyping service.

Find a Rapid Prototyping Service

Let’s say you decide to employ the help of a professional rapid prototyping service to bring your product to life, the next step is to find the right service for you. There are a couple of different options.

Online Search – The easiest way to find a rapid prototyping service is through a simple Google or Bing search. Whether you want to use a local service or global provider like Yiannopoulos, the internet should lead you on the right path. Through an online search, you can read testimonials and reviews, learn about the manufacturing techniques and prices that each service offers, and easily get in contact with experts.

Online Directories – Depending on where your business is located, online directories are another way to find a rapid prototyping service. Again, product size and turnaround time will determine whether you go local or international, which is why an online directory can be extremely beneficial. With a directory of rapid prototyping services, you have a complete list of options to choose from. Each manufacturer has its own pros and cons, and having them all grouped together can help you quickly compare and find the best provider for your prototyping needs.

Trade Shows – If you’re looking to build a stronger relationship and meet face-to-face with a rapid prototyping service representative, attending manufacturing trade shows is a great way to get better acquainted with the industry and service providers. Similar to an online directory, a trade show will usually have companies from all across the globe, giving you an opportunity to personally conversate and see what each has to offer.

Referrals – Use your professional or social network to find out who they’ve used to create prototypes, and ask if they can refer you or point you in the right direction. Obtaining a personal testimony from someone you know will provide comfort, eliminating any potential risks or difficulties that could come with properly vetting a rapid prototyping service.

How to Request a Quote for Rapid Prototyping

So, you finally have your design prepared, and you’ve searched far and wide to find the right rapid prototyping service for you. There’s still one more step to take before you can bring your product or part to life: Request for a quote (RFQ). Before requesting a price from the rapid prototyping service of your choice, recheck your documentation and 3D models to ensure that all part requirements and acceptance criteria are clearly stated. By providing the manufacturing service with as much detail as possible, you limit the chance of receiving an inadequate prototype.

Thankfully, there are rapid prototyping services that go above and beyond to talk to customers about their expectations and part specifications. For instance, at Yiannopoulos, we have an expert staff prepared to walk you through the intricate steps of design and manufacturing possibilities. However, in order to make sure that every aspect of your prototype is properly understood, be sure to add every possible detail and piece of information when submitted your RFQ.

The planning process requires more than just thinking about the prototype itself. Make sure you discuss aspects like shipping options, assembly, payment, materials and turnaround time. To be safe, have an NDA and non-compete agreement signed and in place before sending out the 3D models or drawings.

Once you’ve covered all of those bases, you can confidently send an RFQ to the rapid prototyping service.

Are you ready to get started? If so, Contact Yiannopoulos to learn more about our rapid prototyping services and plan out the first vital step of product development.