Guide: Chinese solid wood furniture is known as the most durable furniture in the world. Many people will be very curious about the secret how it works. Today we are going to reveal the whole manufacturing process of China solid wood furniture for you.

Chinese Solid Wood Furniture

Compare with mechanized production, Chinese solid wood furniture is mostly handmade-based, the manufacturing process of solid wood furniture is quite complicated and it may take a long period from wood to finished production.

1. Sawing

First, after purchase, the logs should be sawed into boards. While sawing we should be according to the dimension of the furniture we need and pay attention to the direction of the wood texture to avoid any unnecessary waste of material.

China Furniture Manufacturing Process-Sawing

2. Drying

Because the whole piece of furniture is made of solid wood, the moisture content of wood is directly related to the adaptability of furniture to seasonal change, and further affects the life of the furniture.

Therefore, the drying of wood is particularly important. If it is not properly dried, all kinds of problems will come out in the following manufacturing process. which will affect the quality of the finished products. Even in the sales and use, the characteristics of the dry shrinkage and wet swelling of wood will also cause various cracks or deformation in some furniture components.

China Furniture Manufacturing Process-Drying

The drying process is generally done in two stages, The first is pre-drying. placing the wood to be processed in a wide-open area to make the pre-drying by air flow and water evaporation.In this way, the moisture content of wood can be reduced to between 20% and 30%..After that, they put them into special drying equipment for further treatment till the moisture content is between 8% and 12%.

3. Woodworking

After the drying is finished, we can enter the formal production process. This step is the most important step in the production of Chinese solid wood furniture. The woodworking can be further divided into the following 6 steps:

Step1: Degisn Drawing And Prepare Bills of Material

The carpentry should design a drawing according to the shape of the furniture we want to customize, and then prepare the bills of materials which figure out the required quantity and dimension of the furniture accurately according to the drawing.

China Furniture Manufacturing Process-Drawing Effect

Step2: Material Selecting and Cutting

As a Chinese common saying says: "30 percent of the material, 70 percent of craft".The quality of material selection of the solid wood furniture will not only directly influence the appearance of art but also affect the service life of the furniture.

The material selecting and batching process is mainly based on different parts of furniture production to choose appropriate materials. Meanwhile, general attention should be paid to the texture of the wood, its color, and size.

China Furniture Manufacturing Process-Cutting

After material selection, cut off the white skin and the residue that cannot be used at both ends first,. and then cut the wood into the specification pieces again according to the size of the bills of material. While cutting we should follow the direction of the grain,and keep the strength evenly to ensure the cutting effect becomes smooth and neat.

Step3:Planing

After cutting, the next step is planning. It must be planned along the grain. and not the opposite, and do not plane or along the diagonal across the grain. All the finished materials should be placed together according to the same specifications to avoid excessive storage time and extrusion deformation.

China Furniture Manufacturing Process-Planing

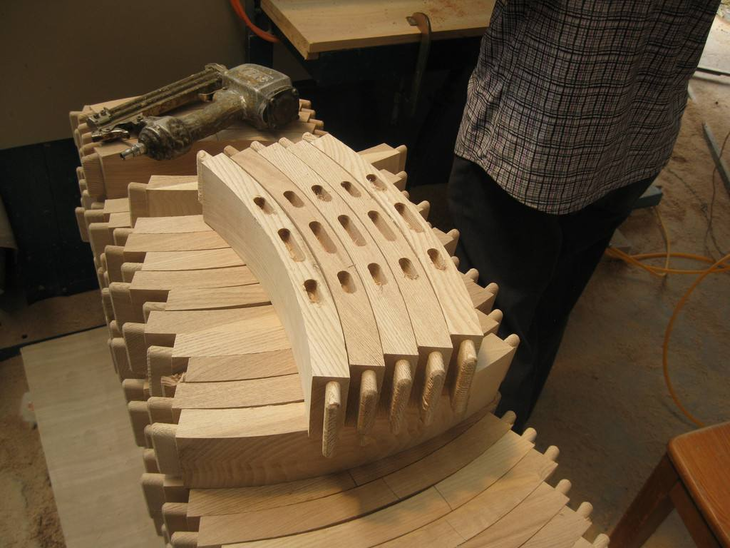

Step4:Mortising And Drilling

After planning the materials can be used to mortise and drill, because all the components of solid wood furniture are connected by mortise and tenon structure. Mortise and tenon structure is is a smart combination of more and less, higher and lower, and longer and shorter among wood pieces.

It can effectively limit the twisting of wood pieces in all directions, and will not cause the timber to split. It ensures the integrity of furniture and greatly improves the internal quality of solid wood furniture.

China Furniture Manufacturing Process-Mortising

Each mortise and tenon has a definite function of fixing and locking, which can effectively disperse the bearing capacity of the furniture in the overall assembly and cannot see the cross-section of the wood in the appearance of the furniture. These exquisite tenon and tenon structures form the unique technological features of solid wood furniture.

China Furniture Manufacturing Process-Drilling

Step5:Drawing Line And Rounding

After finishing the mortise and drill, it is to start drawing lines and rounding. Nowadays, many Chinese solid wood furniture factories use machines to complete the processing. Drawing a line means putting the designed template pattern on the part, drawing the outline with a pen, and using a band saw machine to see the contour of high and low fluctuation according to the line drawn.

The main purpose of rounding is to make the surface of the material look more rounded and feel more comfortable.

China Furniture Manufacturing Process-Drawing Line

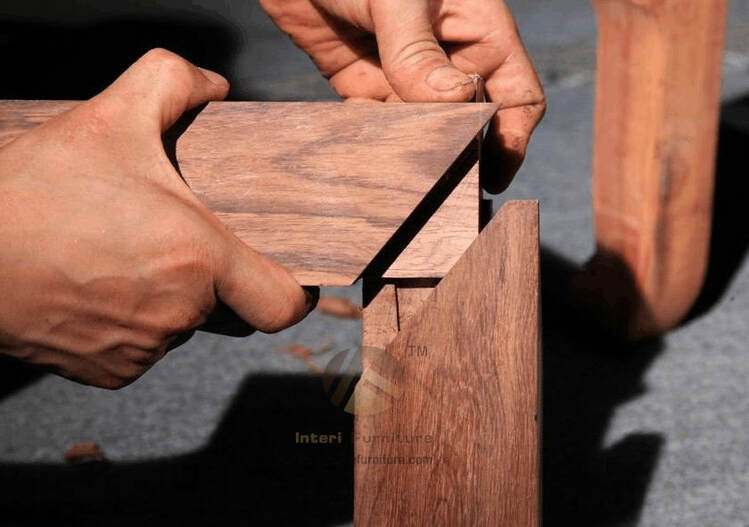

Step6: Mortise-and-tenon Checking

The final step in the woodworking process is to check the quality of mortise and tenon. This step is mainly to check whether the mortise and tenon are appropriate in size and rigorous and whether they are bent or warped, then assemble them into a relatively independent structural component unit.

China Furniture Manufacturing Process-Mortise-and-tenon Checking

4. Manual Carving

In order to make solid wood furniture look more beautiful, Chinese furniture manufacturers tend to use a few simple or complex carving techniques for decoration. There are a variety of different carving techniques in China. Each kind of this technique is different, and each of them has its own characteristics.

We should say manual carving takes more than half of the whole manufacturing time of solid wood furniture, and the requirements for manual carving are very strict. In the engraving workshop, every carver should concentrate on his work at hand. If there is a mistake, the whole material can not be repaired again. This will cause the quality of finished solid wood furniture to be badly affected.

China Furniture Manufacturing Process-Manual Carving

5. Assembling

Place the different furniture components in order. Assemble them in different order, techniques, and methods according to the characteristics of each set of furniture. While assembling the mortise and tenon, we should pay attention, can not be a sudden, hard strike. We need to get the interface right and strike it with a wooden hammer. And it needs to be padded with a piece of wood to prevent it from leaving the hammer's mark and affecting the appearance of the furniture.

China Furniture Manufacturing Process-Assembling

6. Scraping And Polishing

After assembling, the surface of the furniture needs to be scraped and polished, which is an important step in the China solid wood furniture manufacturing process. Lots of the surfaces of solid wood furniture that we see in the furniture market are all hand polished.

Use a scraper to scrape first commonly, then polish many times with more and more fine sandpaper until the mark of the coarser sandpaper is worn away.

The semi-finished furniture after scraping and polishing has smooth lines, a flat surface without wave feeling, a smooth and clear texture, and a smooth and comfortable feel.

China Furniture Manufacturing Process-Polishing

7. Painting And Waxing

●Painting

Step 1: Generally, the painting process will take a long time to complete for solid wood furniture usually needs to be painted several times.

Step2:Use an appropriate amount of chemical blending agent when painting. Every place must be painted without being left out.

Step 3: Do not stop anywhere in the painting process, and it must be done in one go.

China Furniture Manufacturing Process-Painting

●Waxing

Step 1: Before waxing, you can put a layer of anti-cracking agent on it, which can better lock up the moisture, and then place it in the shade for a day.

Step2:The parts shall be polished with sandpaper after drying. The purpose of polishing is to make the furniture brighter and more delicate. All parts should be polished in place. After polishing, brush the dust off, especially the recessed parts, and then blow the surface clean with the hair dryer.

China Furniture Manufacturing Process-Waxing

Step3:Choose the best beeswax. When waxing, you can put beeswax into an iron bucket, and then heat it on the stove. After beeswax is dissolved, you can even rub it on the surface of parts with a soft pure cotton cloth. When you polish it, you can use larger force repeatedly to ensure that the wax can penetrate into parts well.

Step 4: Place the finishes for one day after waxing, and polish it again after the wax has fully penetrated into the wood.

After completing all the above processes,we can see a finished Chinese solid wood furniture at the moment.

China Solid Wood Furniture

We, Interi Furniture, have been working in this field for more than 13 years. If you are wanting to know more about the solution of China solid wood furniture or looking for a professional China furniture manufacturer for your residential or commercial project, we will be pleased to help. Please kindly forward any of your inquiries via [email protected].